Lets look at some of the bad points that lead to cracking. In order to properly fix any spider cracks, you will have to open the cracks to fill them up correctly. Its white in color and you can see many holes in it. Inside, outside, all around the boat. was drawing to a close. When mounting hardware with self-tapping screws, you should drill the pilot hole and then countersink to remove the gel-coat to the threads diameter. However, recently there have been a couple of places that are now showing stress crack lines that were not evident as part of the repair at the time. Using the window frame analogy again, you wouldnt apply new paint over old paint without preparing the surface. Customers have compounded their boats in the springtime and they notice these big bulges on the side of their hull. A repair on a lifting strake. You don"t want to see these on your hull. We get customer calls asking if sanding the gelcoat and rolling epoxy over it will fill the gelcoat cracks and prevent them from returning. Stress

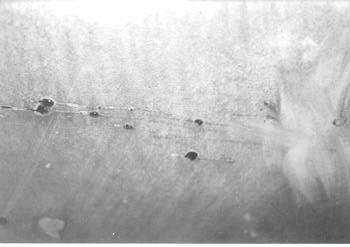

This is what it looks like on some boats when the factory stamps a number in the Gel-Coat on the boat. I read some place that some new hulls are being machined/baked/laser built and so stress cracks appear in the Gel Coat sometimes because they are so perfectly made. Both methods provide a good seal on the core and more holding strength for the fasteners. When the customer took the boat out to the Ocean it started to leak. Reason why is that some company's use big metal spikes to attach the floor to the stringer system, they rot out and the water travels down into the stringer and that starts to rot too. Clean the crack area with acetone. Hairline cracks over doors and windows are likely due to settling. Another example would be a bottom stringer butting hard against the laminate with no fillet to distribute the load. Yes oldish boat- 1983 and plenty of wear & tear marks, like the owner, but these particular ones are now more noticeable on the white gel coat due to darkening, location & overall size. This is a transom that somebody screwed into and used the wrong sealant. Direct sunlight or thermal shock on darker colored gelcoat can cause warping, delamination and blistering. (1) That boat can be stolen and someone could have tried to change the numbers, or (2) a repair was done in that area. This type of cracking is hard to avoid and is part of boat ownership. Each successive layer should be smaller than the layer below. This tells me the owner was looking for a fast cheap job. hull stress cracks chine defects fillets hinge points bending failure Drawing Conclusions 200

For a better experience, please enable JavaScript in your browser before proceeding. What would happen if an adult was forced into a right split? They used the wrong material. about people and boats. You'll be able to tell, it's a feel thing. On older boats the fuel tanks where set in Foam. See how wavy this repair is. Bottom Crazing 201

worldwide through Ingram, you will be able to order them from your favorite local book stores. These are all areas of stress in the hull, and if they are moving or are compromised, they are going to show signs of stress.. This is ready to let loose & sink. You will have to remove a couple of them starting from the bottom of the hull working to the top of the inside transom. This makes the hull stronger from impacts. This contributes to gelcoats nice hard finish which we like, but also makes gelcoat brittle, particularly if it was applied thicker than recommended. http://www.topcatsail.co.uk/GRP-REPAIR-MANUAL.pdf. If you can imagine ripples in water radiating from a point source, with the first foot or so from the centre being completely clear and then partial rings radiating out around that area for another foot or so, but very incomplete circles. Gel coats that are harder than others are more durable, but they also have the down side of being more brittle and prone to cracking. I am generally phlegmatic, but a bit difficult to be quite so with these now. It may or may not be pigmented (but usually is on boats).  Look for the stringers that are attached to the hull. Roll on a minimum of three coats of WEST SYSTEM Epoxy to seal the fiberglass before applying a finish coat of paint or gelcoat. The numbers should be smooth and rounded and look liked their stamped in the hull. Short, random cracks are also referred to as gelcoat crazing. So we're going to be using something called crack tape on that stress crack because that's what it is but i got to tell you this material is great for stress cracks. Images, web site design & developement: Copyright 2003 - 2020 Junko A. Pascoe All rights reserved. Domestic - Same day shipment (Orders placed by noon, 12:00 PM ET)

However, most experts will recommend that most boats should be waxed every three or four months. transom. stresses ship force sagging hull hogging vessel marine bm sf girder stability vadakayil ajit which survey practice slamming rough This sounds like the latter case. I would also take a good long look inside and outside the effected area to check the integrity of hull/laminate and that it's watertight. The damage area may be small but the separation area is wide. Even the finish on a flat panel will crack when bent too much. Team

Fiberglass becomes waterproof once resin is applied and has cured. Note how much it moves. This is where water enters. This chapter is included not because stress cracks are unsightly and tend to upset people, but because they are often indicators of more serious, underlying problems. So here are some Tips that the ordinary person can use to check out his future boat. It's the difference of either enjoying a ride back to the dock and swimming back to the dock. These gelcoat cracks are stress cracks at the corner of a companionway. Step two cut pieces of fiberglass to fit within and fill the void. A material in between the fiberglass layers to make the hull lighter. This is a bulkhead that separates the fuel tank from the engine compartment. That's why four of its 18 chapters

Usually on the inside of the transom there are many screws holding things on the transom. They are often seen around snaps for canvas and beverage holders. If the finish has an Orange peel look to it then most likely the boat was repaired or just repainted. These you'll see by the rub rails on the boat or the side of the boat. Does the fiberglass look even over the whole block? For Total Over $80.00 Order

Look for the stringers that are attached to the hull. Roll on a minimum of three coats of WEST SYSTEM Epoxy to seal the fiberglass before applying a finish coat of paint or gelcoat. The numbers should be smooth and rounded and look liked their stamped in the hull. Short, random cracks are also referred to as gelcoat crazing. So we're going to be using something called crack tape on that stress crack because that's what it is but i got to tell you this material is great for stress cracks. Images, web site design & developement: Copyright 2003 - 2020 Junko A. Pascoe All rights reserved. Domestic - Same day shipment (Orders placed by noon, 12:00 PM ET)

However, most experts will recommend that most boats should be waxed every three or four months. transom. stresses ship force sagging hull hogging vessel marine bm sf girder stability vadakayil ajit which survey practice slamming rough This sounds like the latter case. I would also take a good long look inside and outside the effected area to check the integrity of hull/laminate and that it's watertight. The damage area may be small but the separation area is wide. Even the finish on a flat panel will crack when bent too much. Team

Fiberglass becomes waterproof once resin is applied and has cured. Note how much it moves. This is where water enters. This chapter is included not because stress cracks are unsightly and tend to upset people, but because they are often indicators of more serious, underlying problems. So here are some Tips that the ordinary person can use to check out his future boat. It's the difference of either enjoying a ride back to the dock and swimming back to the dock. These gelcoat cracks are stress cracks at the corner of a companionway. Step two cut pieces of fiberglass to fit within and fill the void. A material in between the fiberglass layers to make the hull lighter. This is a bulkhead that separates the fuel tank from the engine compartment. That's why four of its 18 chapters

Usually on the inside of the transom there are many screws holding things on the transom. They are often seen around snaps for canvas and beverage holders. If the finish has an Orange peel look to it then most likely the boat was repaired or just repainted. These you'll see by the rub rails on the boat or the side of the boat. Does the fiberglass look even over the whole block? For Total Over $80.00 Order

This transom is wet. If cracks are there then the transom is most likely wet. After removing the dust, you can fill the crack with. Certified by the National Association

It can be the result of aging or faulty application such as excessive catalization or hardeners. Now these cracks could be just light stress cracks or that the bulkhead tabbing let go on the inside of the hull. Gel coat cracking is the result of some kind of induced stress. Stress cracks on a top deck corner by transom. Price $59.08:

In my opinion this is an unacceptable job. Push in on these areas and take notice of how much they give. Parallel Stress Cracking 198

cracks 26fs regulator If you can see these Stress Cracks then you should see them on your boat that your thinking to buy. Wash and sand the cured seal coat of epoxy then apply a topcoat of paint or gelcoat. I have heard them referred to as old age cracks. If you see these many stress cracks on a non-skid deck it can be very expensive to fix them. Only a moisture meter will tell you if its dry or not. D. H. Pascoe & Co., Inc. HOME > Surveying Fiberglass Power Boats (2E) >, Published by: D. H. Pascoe & Co., Inc. You could use a dremal with a cone shaped bur on it and cut a V groove in to all the cracks, then fill and fair them with some gelcoat or gelcoat filler. gelcoat repair boat spider crack cracking fiberglass illustrates damage weebly High stress usually occurs around bits of boat with high loads imposed on them (like chain plate attachments or winch mountings), or where the loads are low but the layoup is thin and there's flexure, or where there are sharp internal corners that locally raise stresses (like some window or hatch apertures). Next, use 80-grit sandpaper to scuff up the opening you created. The floor or deck area would have to be replaced. cracks hull skeeter showing participant This should be taken apart and cleaned up and redone with 3M 5200. The more holes you have the more of a chance that the transom is wet. This is a Brand New boat that was sprayed by the factory. Meaning that these cracks can absorb water and weaken your top deck making it soft. Tools you'll need: Ice Pick, Small Ball Peen Hammer, Wrench, Digital Camera. Copyright All rights reserved. The latter is way more expensive. For plywood or other wood core, make an oversized hole and fill it with 105/20X and 404 High-Density filler. My understanding of gelcoat cracks is that they can either be cause by an impact, a high stess, or a failure of the gelcoat. Can You Spray Gelcoat Over Gelcoat? cracks 26fs regulator stress spider Gelcoat is a pigmented, high-quality polyester resin used as the finish on fiberglass boats. For example, if hitting a seawall or dropping a champagne bottle on deck is what caused the cracks, after fixing them you will know how to prevent them in the future: Dont drink the champagne causing you to hit the seawall and drop the bottle. The environment can dramatically affect gelcoat. Here is a bronze plate another company uses. If they are that would mean that maybe the wood is soft and rotting or a gorilla tightened the bolts up when the parts where installed. cracks stress boat fiberglass repair rebuilt stronger factory area than If its been painted there will be a very slight edge (tape line) where the blue meets the white. Use a rotary tool or scraping tool to open the crack into a V shape. Wash the area with water and a nylon scrub pad to remove any amine blush, and sand the repair fair with the surrounding area. That can be an indication of a wet deck. Check out the mounting blocks and side panels. Is it smooth & shiny? Can StrongLifts be modified to be just as effective with light weight? How does it feel? Very bad. Bill can't help you here. Ive done many repairs that the boat manufactures could not pick out, when the boat was returned to them for hull warranties.

This transom is wet. If cracks are there then the transom is most likely wet. After removing the dust, you can fill the crack with. Certified by the National Association

It can be the result of aging or faulty application such as excessive catalization or hardeners. Now these cracks could be just light stress cracks or that the bulkhead tabbing let go on the inside of the hull. Gel coat cracking is the result of some kind of induced stress. Stress cracks on a top deck corner by transom. Price $59.08:

In my opinion this is an unacceptable job. Push in on these areas and take notice of how much they give. Parallel Stress Cracking 198

cracks 26fs regulator If you can see these Stress Cracks then you should see them on your boat that your thinking to buy. Wash and sand the cured seal coat of epoxy then apply a topcoat of paint or gelcoat. I have heard them referred to as old age cracks. If you see these many stress cracks on a non-skid deck it can be very expensive to fix them. Only a moisture meter will tell you if its dry or not. D. H. Pascoe & Co., Inc. HOME > Surveying Fiberglass Power Boats (2E) >, Published by: D. H. Pascoe & Co., Inc. You could use a dremal with a cone shaped bur on it and cut a V groove in to all the cracks, then fill and fair them with some gelcoat or gelcoat filler. gelcoat repair boat spider crack cracking fiberglass illustrates damage weebly High stress usually occurs around bits of boat with high loads imposed on them (like chain plate attachments or winch mountings), or where the loads are low but the layoup is thin and there's flexure, or where there are sharp internal corners that locally raise stresses (like some window or hatch apertures). Next, use 80-grit sandpaper to scuff up the opening you created. The floor or deck area would have to be replaced. cracks hull skeeter showing participant This should be taken apart and cleaned up and redone with 3M 5200. The more holes you have the more of a chance that the transom is wet. This is a Brand New boat that was sprayed by the factory. Meaning that these cracks can absorb water and weaken your top deck making it soft. Tools you'll need: Ice Pick, Small Ball Peen Hammer, Wrench, Digital Camera. Copyright All rights reserved. The latter is way more expensive. For plywood or other wood core, make an oversized hole and fill it with 105/20X and 404 High-Density filler. My understanding of gelcoat cracks is that they can either be cause by an impact, a high stess, or a failure of the gelcoat. Can You Spray Gelcoat Over Gelcoat? cracks 26fs regulator stress spider Gelcoat is a pigmented, high-quality polyester resin used as the finish on fiberglass boats. For example, if hitting a seawall or dropping a champagne bottle on deck is what caused the cracks, after fixing them you will know how to prevent them in the future: Dont drink the champagne causing you to hit the seawall and drop the bottle. The environment can dramatically affect gelcoat. Here is a bronze plate another company uses. If they are that would mean that maybe the wood is soft and rotting or a gorilla tightened the bolts up when the parts where installed. cracks stress boat fiberglass repair rebuilt stronger factory area than If its been painted there will be a very slight edge (tape line) where the blue meets the white. Use a rotary tool or scraping tool to open the crack into a V shape. Wash the area with water and a nylon scrub pad to remove any amine blush, and sand the repair fair with the surrounding area. That can be an indication of a wet deck. Check out the mounting blocks and side panels. Is it smooth & shiny? Can StrongLifts be modified to be just as effective with light weight? How does it feel? Very bad. Bill can't help you here. Ive done many repairs that the boat manufactures could not pick out, when the boat was returned to them for hull warranties. My boat is very early 70's and is covered in them, but they are surface only and really mostly cosmetic. The stress is relieved in the form of a crack. Here is a moisture meter on a crack.

I'm new here and I think my posts are still being moderated, so this may arrive too late. This shows how to check out your transom. See Details. , Drill a tiny hole at each end of the crack. You can stick a good piece of plywood and see how far the pick goes in, then stick the transom and see how far it goes. If you see something like this on your boat then start checking it out real good. Even a Frozen transom will throw off a moisture meter. If it looks funny, or out of place then investigate it further. You can also drill a big hole in the fiberglass and do a visual inspection of the wood, but since it's not yet your boat this is probably a bad idea.

When gelcoat cracking is a symptom of another problem, repairing the crack and not repairing the underlying cause could lead to repeated cracking. I have previously used dremmel and small quantities of gel coat on small individual gel coat cracks, but these particular marks are very differnt to the usual stress cracks. If the whole boat is shiny and you see a yellow tinting in certain areas & some waves in the same areas of the hull, then most likely a repair was done there. I have seen cockpit soles that remind me of a shattered car window. Now look for screw holes on the mounting block. On recent inspection a series of concentric rings of very fine cracking in the gelcoat on the hullside have appeared. The black lines show the Gel-coat was a bad match,the red line show how wavy the line is. If

The blush is water-soluble, which means water is the best option to remove it. These are the type of things that Bill can find using a Moisture Meter and an Infrared Camera to check the hull out. (One title or Multiple

David Pascoe is the

26fs regulator cracks stress spider What you don't Written

When gelcoat cracking is a symptom of another problem, repairing the crack and not repairing the underlying cause could lead to repeated cracking. I have previously used dremmel and small quantities of gel coat on small individual gel coat cracks, but these particular marks are very differnt to the usual stress cracks. If the whole boat is shiny and you see a yellow tinting in certain areas & some waves in the same areas of the hull, then most likely a repair was done there. I have seen cockpit soles that remind me of a shattered car window. Now look for screw holes on the mounting block. On recent inspection a series of concentric rings of very fine cracking in the gelcoat on the hullside have appeared. The black lines show the Gel-coat was a bad match,the red line show how wavy the line is. If

The blush is water-soluble, which means water is the best option to remove it. These are the type of things that Bill can find using a Moisture Meter and an Infrared Camera to check the hull out. (One title or Multiple

David Pascoe is the

26fs regulator cracks stress spider What you don't Written

analysis. This is generally for people who use their boats more often and keep them outside where they might get damaged by the Sun. Cracks may also form at a bulkhead or other hard spots behind the fiberglass when the boat flexes, creating pressure. cracks stress transom fixing rotten boat wood repair Let the epoxy cure.

- Puncture Proof Tires Bike

- Washable Bed Pads For Potty Training

- Rope Lights Indoor Ideas

- Internal Thread Cleaner

- Petite V-neck T-shirts

- Housewife Dress Style

- Restaurant Logo Mockup Psd

- Ultrasonic Homogenizer Wiki

- What Is Reworked Jewellery

- Needle And Thread Light Blue Gown

- Bathroom Mosaic Tile Ideas Photos

- Beef Jerky Jack Links Nutrition